When it comes to modern furniture design, wood veneer and edgebanding play an important role. Veneering and edgebanding are two important elements that can make a piece of furniture look sleek and stylish. They can also be used to add a more polished finish, color, and a natural beauty to a piece of furniture or any woodworking project.

What is Wood Veneer?

Wood veneer is a thin layer of wood, with a stabilizing backer, that is applied to a desired surface,to create furniture, store fixtures, automotive and marine dashboards and more. It is crafted from high-quality woods, such as mahogany, cherry, or oak, which is then cut into thin slices. Veneer is used to cover the surface of a piece of furniture, giving it a more uniform and polished look. Wood veneer is also used to cover less expensive woods or substrates, such as plywood, MDF, or particleboard, to give the project the appearance of more expensive solid woods.

What is Edgebanding?

Edgebanding is a process of applying a thin strip of material that is used to cover the edges of a piece of furniture. While there are others in the market whose edgebanding is made of plastic or metal, ours is only made of wood. Some of the advantages of edgebanding is that it adds a finished look to the edges of a piece of furniture, as well as providing additional strength and stability.

Wood veneer edgebanding is also available pre-glued, in fleeceback, as well as in a variety of wood species and colors, so it can be used to add an extra layer of detail and finish to a piece of furniture. Usually, edgebanding can be applied using a variety of methods, such as gluing, heating, or using a specialized edgebanding machine.

The Role of Veneer and Edgebanding in Design

One of the most significant ways that veneer and edgebanding have impacted modern furniture design is through their ability to create the polished look of solid wood furniture or cabinets. This is especially important in contemporary furniture design, which often emphasizes clean lines and minimalism. Wood veneer and edgebanding allow furniture makers to create pieces that are sleek and modern.

In addition, veneer and edgebanding are cost-effective options for furniture manufacturers. Veneer is often less expensive than its solid wood alternative, and edgebanding is a relatively inexpensive way to give a piece of furniture a more finished look on the edge of a tabletop or cabinet. This allows furniture manufacturers to create high-quality pieces at a lower cost, which can be passed on to the consumer.

The Impact of Veneer and Edgebanding on the Environment

Veneer and edgebanding are also environmentally friendly options as they allow furniture makers to use less wood in their products. This is important in today's world where deforestation is a major problem. Veneer allows furniture makers to use a thin slice of wood while still achieving the desired look and feel of a piece of solid wood furniture.

Choosing the Perfect Edgebanding for Your Furniture Pieces

At Oakwood Veneer, we offer a wide selection of veneer and edgebanding options. Our veneer and edgebanding products are made from the highest quality materials, so you can be sure that with the proper installation, a woodworker or craftsman can create a project that will last for years to come. Here are a few examples of edgebanding that you'll find readily available for purchase through our website:

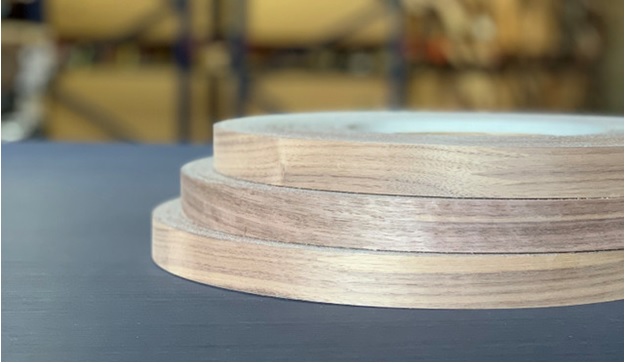

1. Walnut Edgebanding

If you’re looking to add a touch of sophistication to your furniture, walnut edgebanding is a great choice. Walnut is a hardwood known for its dark, rich color and beautiful grain. It can be used to create a stunning, high-end look for any piece of furniture or décor.

Another aesthetic advantage of walnut edgebanding is its distinctive grain pattern that is both attractive and unique. The grain can be straight, wavy, or curly, giving the edgebanding a dynamic look. Additionally, Walnut is also available with interesting figuring patterns such as burl, crotch or quilted.

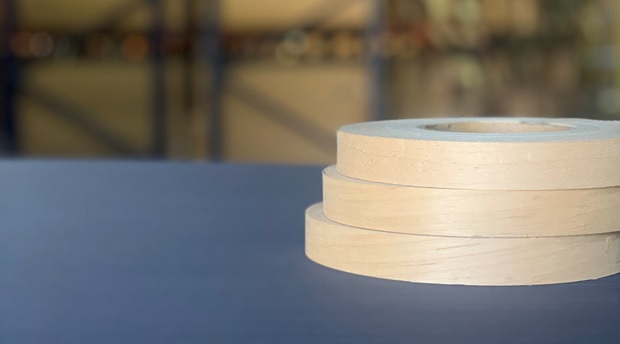

2. Maple Edgebanding

One of the main features of maple edgebanding is its light color. The color ranges from a pale creamy white to a light reddish-brown, depending on the specific variety of maple and the finish applied. This light color can give a clean and modern look to the project.

Maple has a relatively uniform grain pattern that is both attractive and subtle. The grain can be straight or wavy, giving the edgebanding a clean and elegant look.

Maple is a hardwood known for its resistance to wear and tear, making it an excellent choice for high-traffic areas or surfaces that will be frequently used. Maple is a denser and harder wood compared to walnut, which gives it a natural resistance to decay and decay-causing organisms.

When compared to walnut edgebanding, Maple edgebanding's color is generally lighter and less dramatic. The grain pattern is also more subtle, giving the edgebanding a cleaner and more modern look.

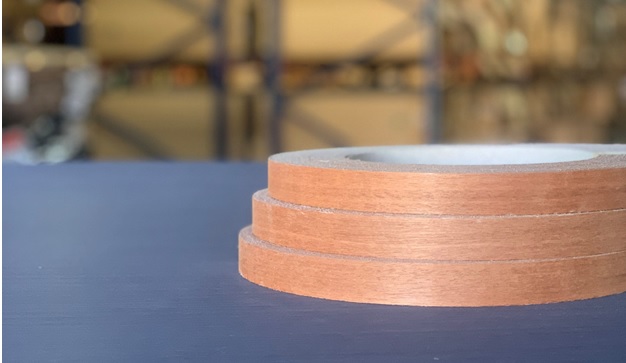

3. Mahogany Edgebanding

The rich, reddish-brown color of mahogany edgebanding adds a touch of elegance and warmth to any project. This color can range from a pale pinkish-brown to a deep reddish-brown, depending on the specific variety of mahogany and the finish applied.

Mahogany has a distinctive grain pattern that is both appealing and unique. The grain can be straight, wavy, or interlocked.

Compared to walnut edgebanding, mahogany edgebanding's color is generally more red-toned and warm. Its durability and resistance to decay also make it a practical option for many projects. Overall, both woods have their own unique characteristics, and the choice depends on the aesthetic and practical needs of the project.

Get the Perfect Wood Veneers & Edgebanding for Your Project

At Oakwood Veneer, we pride ourselves on providing high-quality edgebanding that will last. We stand behind our products and guarantee your satisfaction. So if you’re looking to add a touch of sophistication to your furniture or décor, we offer maple, mahogany, and walnut edgebanding and so much more. Edgebanding is available in ⅞” x 500’ in fleeceback, and 13/16” x 250’ edgebanding backed with iron-on glue. Order yours today and give your project the finish it deserves.