Wood veneer is a thin layer of real wood, typically between 0.5mm and 1.5mm thick, that is sliced or peeled from a log and adhered to a stable core material such as plywood, MDF (medium-density fiberboard), or particleboard to create a veneer sheet or veneer panel. Veneers are used to create the flawless look and feel of solid wood on high-end furniture and surfaces at a lower cost and with less environmental impact than using solid wood alone.

Veneer panels and sheets can be applied to a wide range of products, including cabinets, tabletops, doors, and other furnishings, providing the aesthetic of solid wood while significantly improving stability and reducing costs.

Types and Preparation of Wood Veneer

Material Types of Veneer

-

Raw Veneer: This is unprocessed veneer that can be used on either side. It requires finishing after application.

-

Paper-Backed Veneer: A single veneer layer is bonded to a paper backing, which makes the veneer sheet easier to handle, more flexible, and less prone to splitting—a preferred choice for curved applications.

-

Wood-On-Wood Veneer: Two layers of veneer glued together, which gives the final product more stability.

-

Pre-Finished Veneer: A veneer that is already stained and finished, ready for application.

-

Reconstituted Veneer: Made from fast-growing trees, reconstituted veneers are processed and dyed to mimic more expensive wood grains. Sometimes called recon or engineered wood veneer.

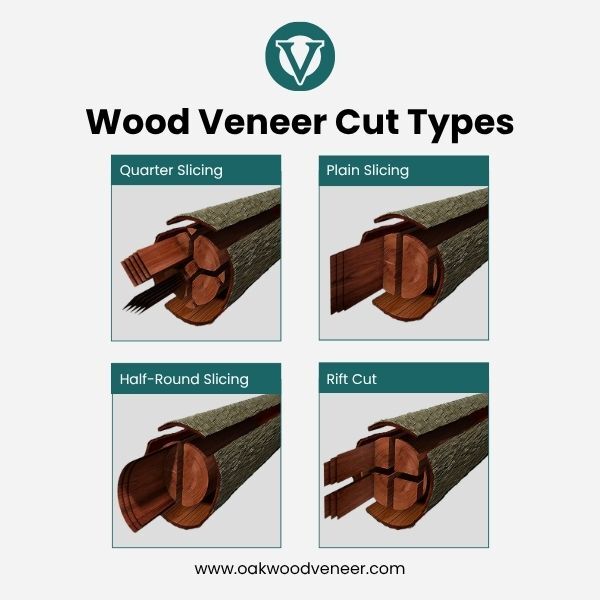

The Four Primary Wood Veneer Cut Methods

Understanding how the veneer is sliced from the log is essential, as the cut method directly dictates the final appearance of the grain pattern. The four primary methods are:

-

Quarter Slicing: The slicing is made perpendicular to the annual growth rings of the tree. This creates a straight grain appearance.

-

Plain Slicing (Flat Cut): By slicing parallel to the center of the log, a raised "cathedral effect" is formed by the innermost growth rings. This is also known as flat cut.

-

Half-Round Slicing: Sliced on an arc parallel to the center of the log, this cut achieves a flat-cut veneer appearance.

-

Rift Cut: This straight grain cut is derived by slicing red and white oak at a slight angle to minimize the irregularities in the wood.

Why Wood Veneer is Essential for Modern Interior Design

Cost-Effective Alternative to Solid Wood

One of the main reasons wood veneer is popular is its affordability compared to solid wood. Since veneer uses only a thin layer of real wood, it significantly reduces the amount of high-grade wood needed, making it more economical. For large architectural projects, sourcing wholesale wood veneer and affordable veneer sheets allows designers to maintain high quality across extensive surfaces while controlling the budget.

Stability and Durability

Solid wood is susceptible to warping, cracking, and movement due to changes in humidity and temperature. Because veneer is applied to stable core materials like MDF or plywood, the resulting veneer panels offer superior resistance to these changes, making them more durable and reliable in fluctuating climates.

Aesthetic Variety and Material Sourcing

Veneer offers unparalleled design options because different wood species can be used for the veneer layer. Exotic woods like mahogany, figured teak, or highly popular species like white oak veneer and walnut veneer sheets can be used to achieve flawless, high-end finishes without the prohibitive cost of using solid wood throughout the project.

Architectural Applications: Wood Veneer for Cabinets, Furniture, and Interior Design

Veneer is the gold standard when specifying high-quality architectural finishes across major projects.

-

Cabinetry: Veneer panels are the standard choice for kitchen cabinets and built-ins, particularly for achieving a luxury look without compromising stability or durability. The popular white oak veneer for cabinets ensures a modern, clean look that resists the humidity and temperature swings common in kitchens.

-

Furniture: Veneer is frequently used in making high-end furniture such as tables, chairs, and dressers, giving them the uniform appearance of solid wood with a far greater lifespan and resistance to movement. The term wood veneer for furniture is synonymous with quality custom-made pieces.

-

Architectural Woodwork: In interior design, veneer sheets and veneer panels are used to create large, striking decorative wall panels, premium doors, and other custom architectural features that require continuity of grain pattern across wide expanses.

-

Musical Instruments: Wood veneers are used in musical instruments like guitars and pianos, where aesthetics and acoustic properties are important.

Key Takeaways

Wood Veneer is a versatile, attractive, and sustainable option for professionals. It offers the rich beauty of real wood while providing better stability and superior cost-effectiveness compared to solid wood. For designers and millworkers, sourcing wholesale veneer sheets provides both quality and affordability for every project.