When selecting a wood veneer, understanding the total sheet thickness is critical for proper installation, durability, and finished appearance. The final thickness of any veneer sheet is determined by combining the ultra-thin face veneer with the backer material.

This page provides the exact measurements for the four primary veneer backers carried by Oakwood Veneer, ensuring you have the precise technical data needed for your project specifications.

The Face Veneer Slice: Consistent and Standardized

For nearly all our stocked veneer sheets, the actual decorative wood slice—the face veneer—maintains a consistent thickness.

-

Veneer Thickness: 1/42" (or 0.0238")

The variations in total sheet thickness and the resulting performance come entirely from the backer material used to provide stability and support.

The Veneer Backer Breakdown: Performance is in the Mil

The backer is not just structural; it determines how the veneer handles moisture, adhesives, and sanding. Here is a breakdown of our key backers and the unique purpose each one serves:

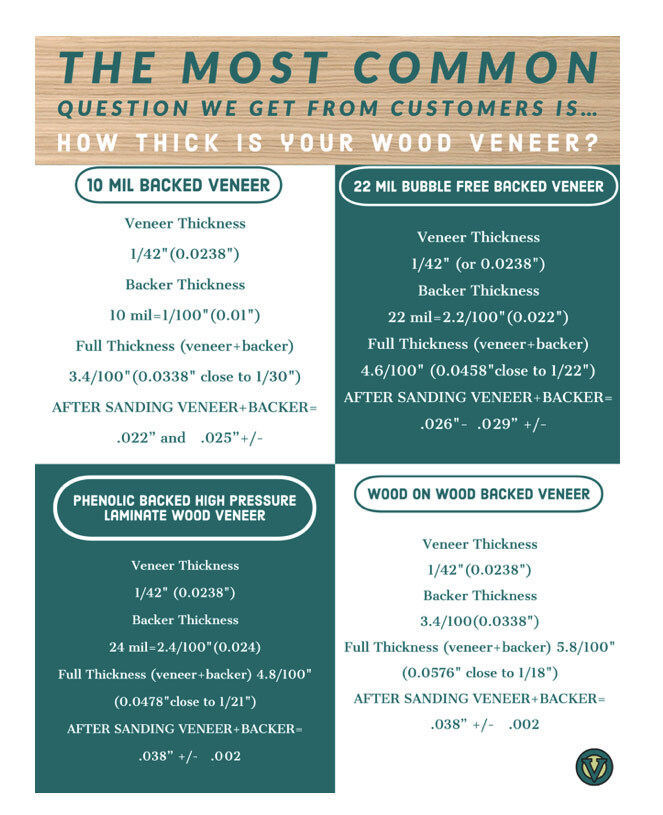

1. 10 Mil Backed Veneer (Paperback)

The 10 mil (0.01") backer is the thinnest paper option, resulting in the thinnest overall sheet. This flexibility makes it ideal for complex applications where the veneer must wrap around tight radii or intricate curves. Its total finished thickness is close to 1/30".

2. 22 Mil Bubble Free Backed Veneer (BFV)

Our Bubble Free Veneer (BFV) is a premium, heavier paper backer designed to eliminate the common problem of air bubbles under the veneer during installation. At 22 mil (0.022") thick, it offers superior stability and resistance to telegraphing adhesive ridges through the finished face. The BFV technology dramatically simplifies the finishing process, and its final thickness is close to 1/22".

3. Phenolic Backed High Pressure Laminate Wood Veneer

Also known as a Phenolic backer, this material offers maximum durability and moisture resistance. The backer itself is approximately 24 mil (0.024") thick, placing the finished sheet close to 1/21" in total thickness. This high-pressure laminate (HPL) construction is the professional's choice for projects requiring exceptional stability and longevity, particularly in commercial or demanding environments.

4. Wood on Wood Backed Veneer (WOW-3 ply)

The WOW backer is a three-ply construction where a non-decorative wood veneer is used as the stabilizer. This creates a highly rigid, dimensionally stable sheet with a total thickness close to 1/8". Because it is composed entirely of wood, it allows the sheet to expand and contract uniformly, which is crucial for applications that require the look and feel of solid wood with maximum stability.

| Backer Type | Veneer Thickness | Backer Thickness | Full Thickness (Veneer + Backer) | After Sanding Veneer + Backer |

| 10 Mil Backed Veneer | 1/42" (0.0238") | 10 mil = 1/100" (0.01") | 3.4/100" (0.0338" close to 1/30") | .022" and .025" +/- |

| 22 Mil Bubble Free Backed Veneer | 1/42" (or 0.0238") | 22 mil = 2.2/100" (0.022") | 4.6/100" (0.0458" close to 1/22") | .026" - .029" +/- |

| Phenolic Backed High Pressure Laminate Wood Veneer | 1/42" (0.0238") | 24 mil = 2.4/100" (0.024) | 4.8/100" (0.0478" close to 1/21") | .038" +/- .002 |

| Wood on Wood Backed Veneer (WOW-3 ply) | 1/42" (0.0238") | 3.4/100 (0.0338") | 5.8/100" (0.0576" close to 1/8") | .038" +/- .002 |

Final Thickness After Sanding

One of the most valuable specifications is the thickness that remains after sanding, as this indicates how much material is available for the final finishing process.

As you can see in the table above, the final thickness remaining after sanding varies significantly by backer type. The Phenolic and Wood on Wood (WOW) backers retain the most material, at approximately .038" +/- .002", offering greater working depth for fine-tuning the surface.

Need a Custom Solution?

While the four backers above cover most commercial and residential applications, we also provide Pressure Sensitive Adhesive (PSA) options and custom Panel Lay Ups. If your project requires non-standard sizes or you need a specialized backer, please contact our team directly for pricing and lead time. All non-stocked items are special orders.