Wood veneer is prized for its natural beauty and cost-effectiveness compared to solid lumber, but like any wood product, it requires diligent care. Repairing and maintaining damaged wood veneer surfaces is essential for preserving the aesthetic value and longevity of cabinets, veneer panels, and fine furniture.

This comprehensive guide provides practical steps for repairing common damage and establishing a robust maintenance schedule to prevent future issues.

Part 1: Repair Techniques for Damaged Wood Veneer

Quickly addressing damage is key to preventing moisture from reaching the core material.

1. Fixing Minor Scratches and Scuffs

For hairline scratches and light surface wear that haven't penetrated the finish:

-

Furniture Marker or Wax Stick: Use a color-matched furniture marker or wax stick. Apply the marker or rub the wax into the scratch, then buff immediately with a soft, clean cloth to blend the repair with the surrounding surface.

-

Furniture Polish: Some minor surface scuffs can be minimized by applying a high-quality furniture polish, which temporarily fills the scratch and restores the surface sheen.

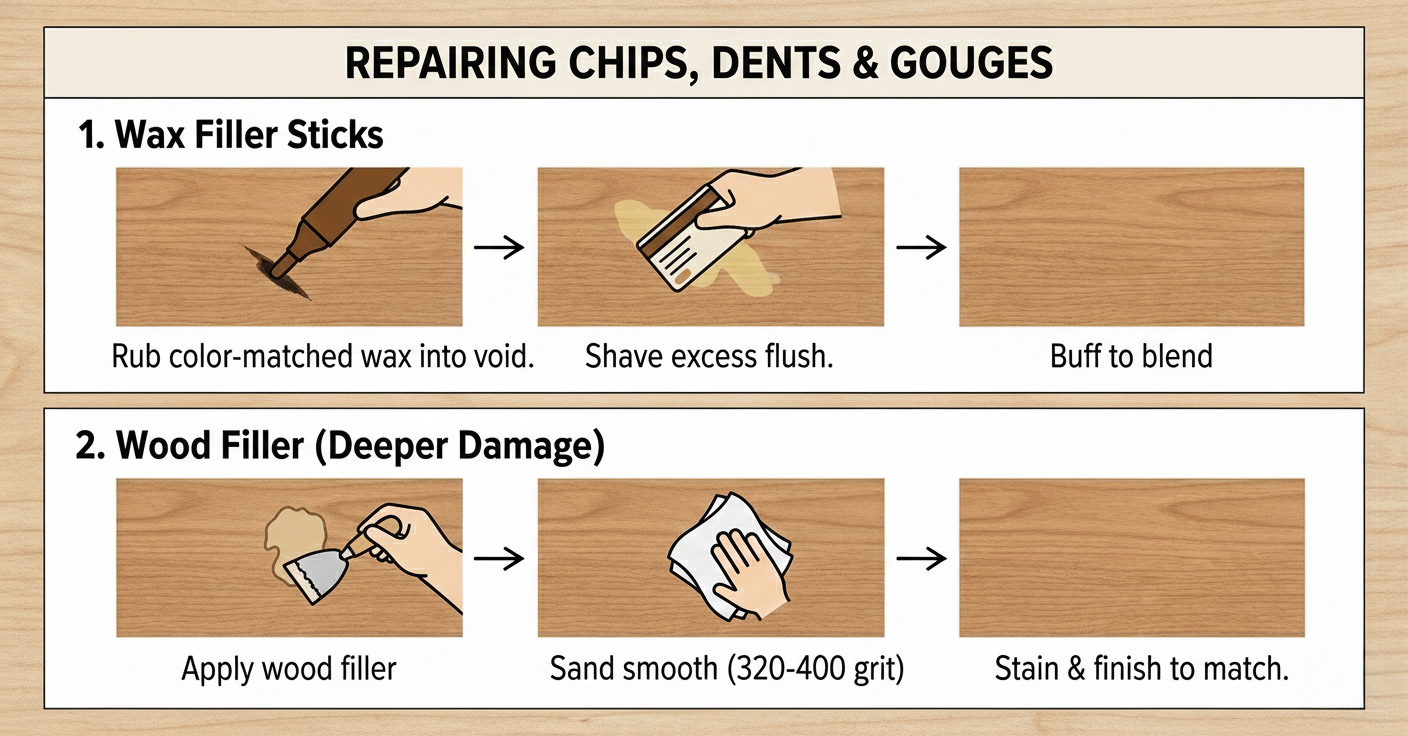

2. Repairing Small Chips, Dents, or Gouges

When surface material is missing but the damage is isolated:

-

Wax Filler Sticks: For small voids, rub a color-matched wax filler stick firmly into the damaged area. Use a plastic scraper (like a credit card edge) to shave the excess flush, and then buff the area to blend.

-

Wood Filler: For deeper chips, use a non-shrinking, solvent-based wood filler that matches the base color of the veneer. Apply the filler with a small putty knife, smooth it, allow it to dry completely, and then carefully sand it with fine-grit (320-400) sandpaper. Finish with a matching stain or clear coat.

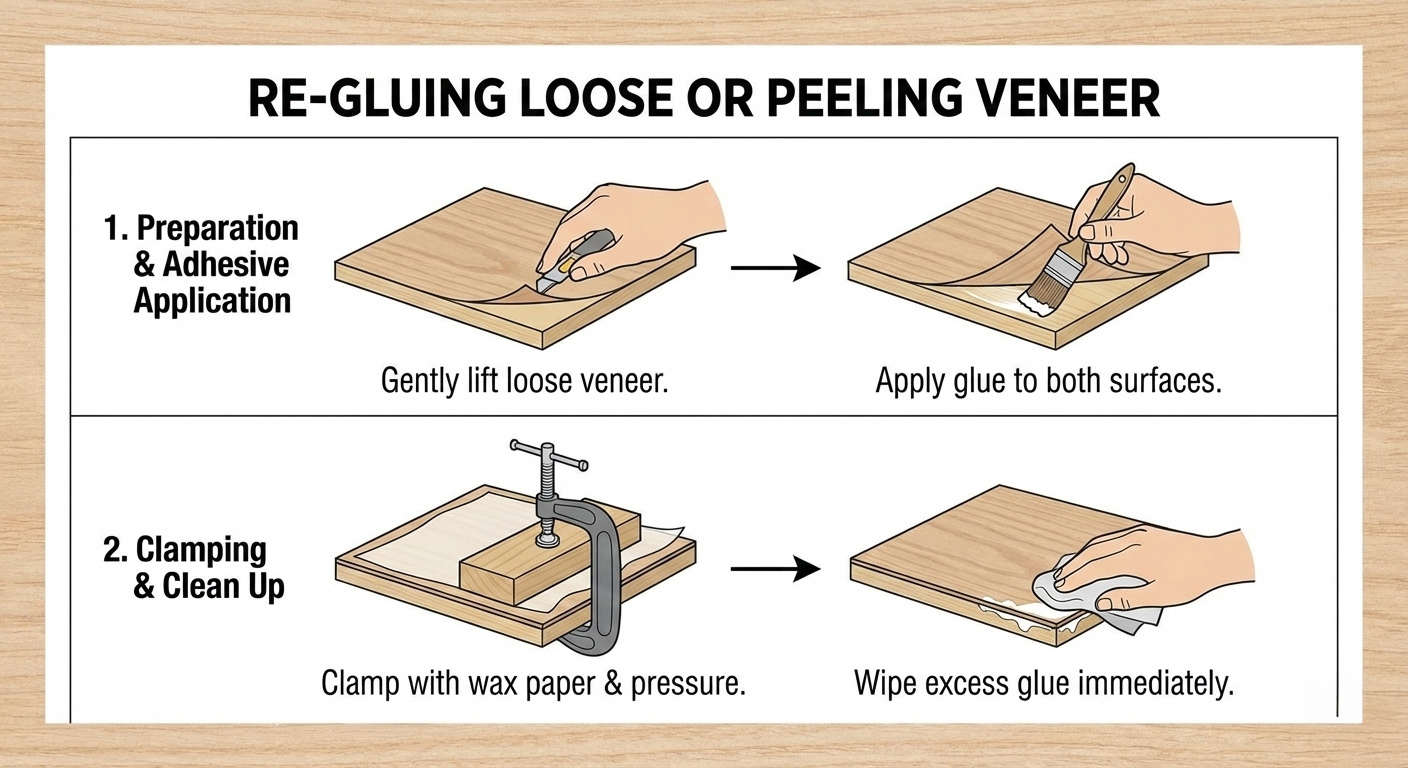

3. Re-Gluing Loose or Peeling Veneer

Veneer can lift or peel from the substrate (often due to heat, moisture, or age). This is most common along edges or corners.

Steps for Re-Gluing:

-

Preparation: Gently lift the loose veneer using a small utility knife or razor blade to allow access to the substrate. Avoid prying or forcing the veneer, which can cause it to crack.

-

Adhesive Application: Apply wood glue or contact cement directly to both the exposed substrate and the underside of the loose veneer section.

-

Clamping: Press the veneer firmly back into place. Place a piece of wax paper over the repaired area (to prevent glue from sticking to the clamp) and use a clamp or heavy, flat object to apply pressure while the glue sets (typically 6-24 hours).

-

Clean Up: Immediately wipe away any excess glue that squeezes out with a damp, warm cloth.

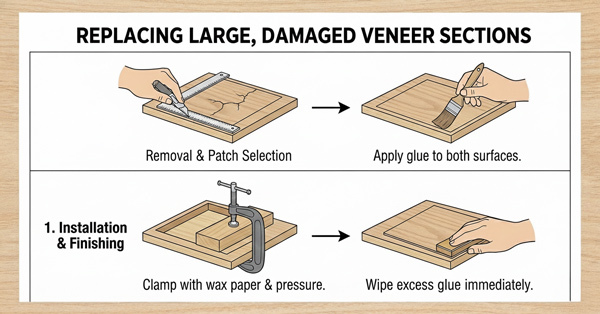

4. Replacing Large, Damaged Sections

If a large area is warped, cracked, or missing, a section replacement may be necessary.

-

Removal: Carefully remove the damaged veneer using a sharp utility knife, scoring the perimeter and peeling or chiseling out the damaged material down to the core.

-

Patch Selection: Cut a matching piece of veneer sheet or flexible sheet veneer to fit the exact size of the removed section. Use the original removed piece as a template for accuracy.

-

Installation: Apply wood glue or contact cement to the exposed substrate and the back of the new piece. Press the new veneer firmly into the opening.

-

Finishing: Clamp or weigh the new veneer patch down until the glue is fully cured. Lightly sand the edges of the patch to ensure they are perfectly flush with the existing material, then apply a protective finish to blend the color and sheen.

Part 2: Essential Maintenance for Long-Term Veneer Preservation

For furniture makers and millworkers, educating clients on proper maintenance is crucial for ensuring the longevity of veneer panels and finished pieces.

1. Routine Cleaning and Protection

|

Action |

Best Practice |

|---|---|

|

Dusting |

Use a soft, dry microfiber cloth. Dust buildup acts as an abrasive, causing minor scratches over time. |

|

Cleaning |

NEVER use abrasive powders, ammonia-based, or harsh chemical cleaners. Wipe the surface with a barely damp cloth and a mild soap solution, then immediately wipe it dry. |

|

Polishing |

Apply a high-quality furniture polish (avoid silicone-based products, which can build up residue) or a beeswax polish every 6-12 months to maintain luster and create a protective barrier. |

2. Guarding Against Physical and Environmental Stress

-

Prevent Water and Heat Damage: Always use coasters under drinks and mats under hot objects. Immediate spills must be wiped up to prevent moisture from causing the veneer to bubble or warp.

-

Protect from UV Rays: Direct, prolonged sunlight will cause natural wood veneer to fade or change color unevenly. Place veneer panels and furniture away from windows, or use UV-filtering curtains or films. Rotate decorative items periodically to prevent 'sun spots.'

-

Edge Banding Inspection: Pay special attention to the edge banding. The edge is the thinnest point of the veneer application and is most susceptible to chipping or delamination from bumps or moisture. Ensure edges are always sealed and free from lifting.

3. Humidity Control for Architectural Projects

Wood veneer, like solid wood, is a natural material that responds to its environment.

-

Maintain Stable Humidity: For large architectural veneer panels and millwork, maintaining stable indoor humidity (ideally between 40-60%) is vital. Extreme fluctuations can cause the veneer to expand and contract at a different rate than the core material, leading to cracking, splitting, or peeling.

When to Refinish: Restoring Dull Veneer

If your veneer is dull or has extensive shallow scratches, a professional refinish may be required.

-

Light Sanding: Use extremely fine sandpaper (320-400 grit) to lightly sand the surface. The goal is only to scuff the existing finish, not to wear through the thin veneer layer.

-

New Topcoat: Apply a fresh coat of clear varnish, lacquer, or polyurethane.

-

Test First: Always test your sanding technique and topcoat application on a hidden area (like the underside of a table lip) to confirm you do not penetrate the thin wood layer before proceeding to the main surface.